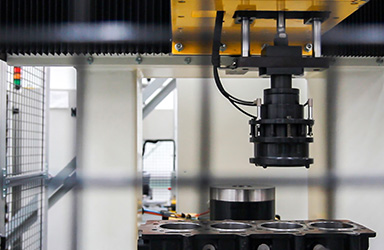

(Summary description)In the process of polyester production, the filtration accuracy of stainless steel sintered felt filter core used for polyester melt filtration is mostly in the range of 10 ~ 25 μm. The filter core is in the shape of candle, with large filtration area, high filtration accuracy, strong pollution resistance, suitable for high temperature, high pressure, high viscosity environment and other characteristics. It should be noted that the candle-shaped filter element has high cleaning requirements and is difficult to clean. In the cleaning process, alkali washing can remove organic matter, and ultrasonic cleaning can remove inorganic matter. The high pressure cleaning machine is mainly responsible for washing the inorganic residue, titanium dioxide (TiO2) and carbon black attached to the surface of the filter element, which can effectively reduce the cleaning time and improve the cleaning efficiency. In addition, improper high pressure water washing can lead to dirt washing into blocks, but reduces the cleaning effect, if the water pressure is too high, it will even break through the filter material and damage the filter element.

(Summary description)In the process of polyester production, the filtration accuracy of stainless steel sintered felt filter core used for polyester melt filtration is mostly in the range of 10 ~ 25 μm. The filter core is in the shape of candle, with large filtration area, high filtration accuracy, strong pollution resistance, suitable for high temperature, high pressure, high viscosity environment and other characteristics. It should be noted that the candle-shaped filter element has high cleaning requirements and is difficult to clean. In the cleaning process, alkali washing can remove organic matter, and ultrasonic cleaning can remove inorganic matter. The high pressure cleaning machine is mainly responsible for washing the inorganic residue, titanium dioxide (TiO2) and carbon black attached to the surface of the filter element, which can effectively reduce the cleaning time and improve the cleaning efficiency. In addition, improper high pressure water washing can lead to dirt washing into blocks, but reduces the cleaning effect, if the water pressure is too high, it will even break through the filter material and damage the filter element.

In the process of polyester production, the filtration accuracy of stainless steel sintered felt filter core used for polyester melt filtration is mostly in the range of 10 ~ 25 μm. The filter core is in the shape of candle, with large filtration area, high filtration accuracy, strong pollution resistance, suitable for high temperature, high pressure, high viscosity environment and other characteristics. It should be noted that the candle-shaped filter element has high cleaning requirements and is difficult to clean. In the cleaning process, alkali washing can remove organic matter, and ultrasonic cleaning can remove inorganic matter. The high pressure cleaning machine is mainly responsible for washing the inorganic residue, titanium dioxide (TiO2) and carbon black attached to the surface of the filter element, which can effectively reduce the cleaning time and improve the cleaning efficiency. In addition, improper high pressure water washing can lead to dirt washing into blocks, but reduces the cleaning effect, if the water pressure is too high, it will even break through the filter material and damage the filter element.